|

Always provide a firm base for the jack* on the ground. (The jack can be found in the vehicle's tool kit). If necessary use a large, strong board or similar support. On a hard, slippery surface (such as tiles) use a rubber mat or similar to prevent the jack from slipping WARNING!.

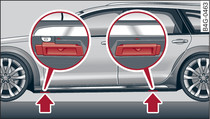

Vehicles with stainless steel trim: Locate the marking by feeling for the raised section under the door sill closest to the wheel being changed Fig. 1. The jacking point is located behind the marking under the door sill.

Vehicles without stainless steel trim: Locate the marking (recess) on the door sill closest to the wheel being changed. The jacking point is located behind the marking under the door sill.

Wind up the jack* under the jacking point until the cylindrical part of the arm -A- Fig. 2 of the jack is below the plastic socket provided.

Align the jack* so that the cylindrical part of the arm -A- fits in the plastic mount under the door sill and the base plate of the jack -B- is flat on the ground. The base plate -B- must be positioned vertically underneath the jacking point -A-.

Raise the vehicle until the defective wheel is clear of the ground.

- Make sure the jack* is stable. If the ground underneath the jack* is slippery or soft, the jack can slip or sink in - risk of injury!

- Use only the jack* supplied with your vehicle to raise the vehicle. If you use a jack from a different vehicle, your vehicle may slip off the jack - risk of injury!

- Apply the jack* only at the jacking points located behind the markings on the door sill and align it properly. Otherwise there is a risk of injury since the jack* can slip off suddenly if it is not properly engaged.

- On vehicles with adaptive air suspension*, the height of the parked vehicle can change as a result of variations in temperature and loading.

- Never start the engine when the vehicle is on the jack – risk of accident!

- If work has to be done under the vehicle, ensure that it is safely supported on suitable stands – risk of injury!